Hydrogen

”The Offshore Gas Station”

A significant opportunity associated with our Ocean Turbine platform is the possibility to produce and store hydrogen gas. The hydrogen will be stored in large tanks on board and beside the platform. Hydrogen gas can be pumped directly to ships and significantly contribute to reducing emissions from offshore traffic.

From Electricity to Hydrogen on Our Platforms

General explanation (for everyone)

We turn moving water into clean hydrogen.

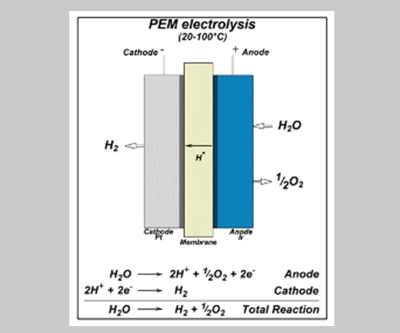

Our submerged platform generates steady electricity from ocean, river, and tidal currents. That electricity powers a PEM electrolyser, which splits purified water into hydrogen (H₂) and oxygen (O₂). We dry and polish the hydrogen to fuel-cell grade and deliver it at ~30 bar for storage or bunkering.

- Input: renewable electricity + purified water

- Output: clean hydrogen (H₂) + oxygen (O₂)

- Why it’s different: steady currents → steady power → predictable hydrogen, with a tiny surface footprint

At a glance (2027)

- Hydrogen quality: fuel-cell grade (ISO 14687), ≥99.97%

- Delivery pressure: ~30 bar (higher pressures available with optional compression)

- Specific Energy Consumption (SEC): ~51 kWh/kg H₂ (boundary: AC-in → H₂-out, no compression)

- Compression energy (add on top of SEC): +2–3 kWh/kg (to 350 bar) • ~+3 kWh/kg (to 700 bar)

- Water use: ~11–15 L per kg H₂ (incl. treatment & cooling)

Advanced details (for engineers & investors)

System overview and boundary

Reporting boundary: AC at electrolyser rectifier input → H₂ at outlet after dryer/polisher (state outlet pressure).

Compression, if used, is shown separately.

Process flow

- Generate (subsea platform): Conveyor-driven shuffle blades on a twin-airfoil (Bernoulli-accelerating) hull drive slow-speed generators for stable AC power.

- Condition (power electronics): AC is rectified to DC; closed-loop control tracks i-V curves and ramping.

- Split (PEM electrolysis): Deionized water is split into H₂ and O₂ across a proton-exchange membrane.

- Polish & dry: Gas clean-up/dryer produces fuel-cell-grade hydrogen (ISO 14687).

- Deliver: H₂ at ~30 bar; optional compression to 350/700 bar adds ~2–3 / ~3 kWh/kg respectively.

- O₂ handling: Safely vented or captured, site-dependent.

What we measure (and publish)

- Specific Energy Consumption (SEC)

SEC=kWh (AC measured at rectifier input)kg H₂ produced\text{SEC}=\frac{\text{kWh (AC measured at rectifier input)}}{\text{kg H₂ produced}}SEC=kg H₂ producedkWh (AC measured at rectifier input)

2027 baseline: ~51 kWh/kg H₂ (no compression)

- Efficiency from SEC

LHV basis: ηLHV≈33.3351×100%≈65%\eta_\mathrm{LHV}\approx \frac{33.33}{51}\times100\%\approx 65\%ηLHV≈5133.33×100%≈65%

HHV basis: ηHHV≈39.4151×100%≈77%\eta_\mathrm{HHV}\approx \frac{39.41}{51}\times100\%\approx 77\%ηHHV≈5139.41×100%≈77% - Purity: ≥99.97% (ISO 14687 fuel-cell grade)

- Water use: ~11–15 L/kg H₂ (incl. balance-of-plant)

- Uptime: ≥90% (rolling 90-day), published via site dashboards

- Compression energy (if used): +2–3 kWh/kg (350 bar), ~+3 kWh/kg (700 bar, fast-fill with pre-cooling)

Instrumentation & method

- Power: Calibrated three-phase analyzer at rectifier input (V, A, PF).

- Hydrogen mass flow: Coriolis meter corrected to actual P/T; continuous purity logging.

- Reporting: We publish SEC with and without compression, and clearly state pressure, test duration, and sampling interval for each campaign.

- Uncertainty: Error bars provided in each site report.

Typical specifications (2027)

| Parameter | Value | Notes |

| Outlet pressure (no compressor) | ~30 bar | After dryer/polisher |

| SEC (no compression) | ~51 kWh/kg | AC-in → H₂-out |

| SEC (with compression) | ~53–54 kWh/kg (350 bar) · ~54 kWh/kg (700 bar) | Adds ~2–3 / ~3 kWh/kg |

| H₂ production rate | Example: ~98 kg/h at 5 MW | kg/h≈kW51\text{kg/h} \approx \frac{\text{kW}}{51}kg/h≈51kW |

| Purity | ≥99.97% | ISO 14687 |

| Water consumption | ~11–15 L/kg | Incl. BOP |

| Uptime | ≥90% | Rolling 90-day target/design |

FAQ

- Why PEM offshore? Fast ramping, high purity, compact footprint, good with quasi-steady currents.

- Where does the oxygen go? Safely vented or captured for local use, depending on permits.

- Does compression change efficiency? We report SEC both ways and always state outlet pressure.

- Water source? Desalinated/treated to OEM limits; closed-loop where feasible to minimize make-up.

Outlook 2030–2035 (what we expect)

- SEC (system, no compression): ~46–48 kWh/kg H₂ for leading PEM systems

- Durability: ~80,000–100,000 h stack lifetimes targeted

- Compression energy: similar physics; ~2–3 kWh/kg (350 bar), ~3 kWh/kg (700 bar)

- Water & purity: essentially unchanged (ISO 14687; ~11–15 L/kg incl. treatment/cooling)

Hydrogen gas production on the platform